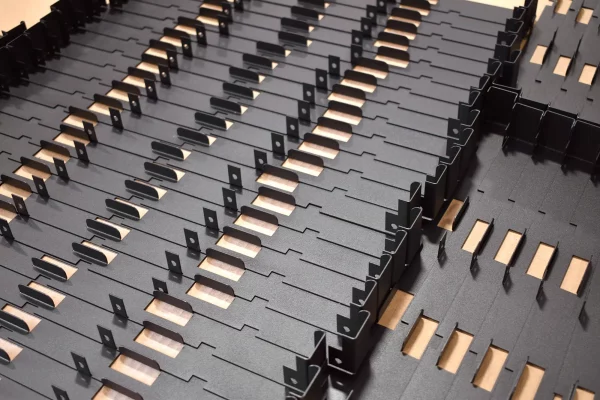

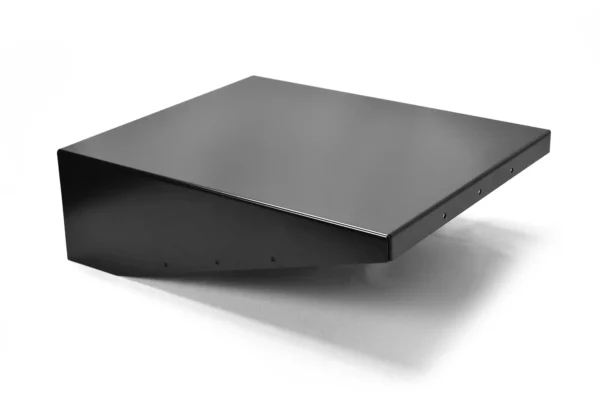

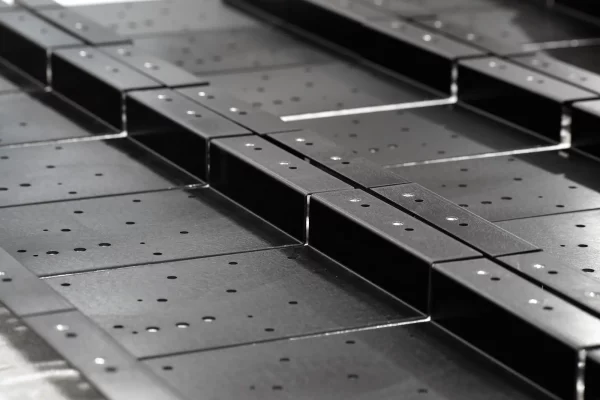

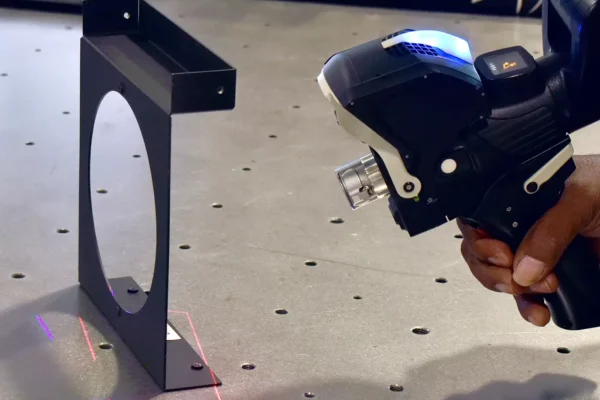

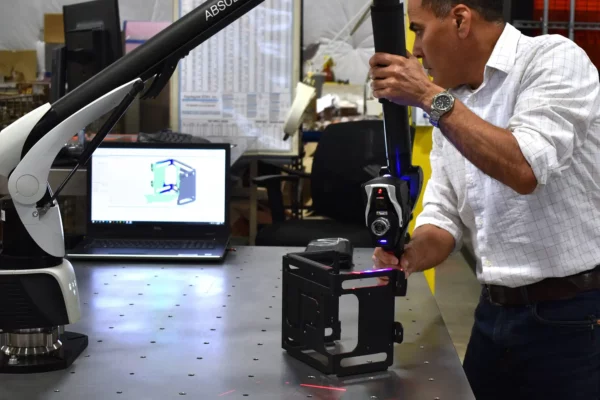

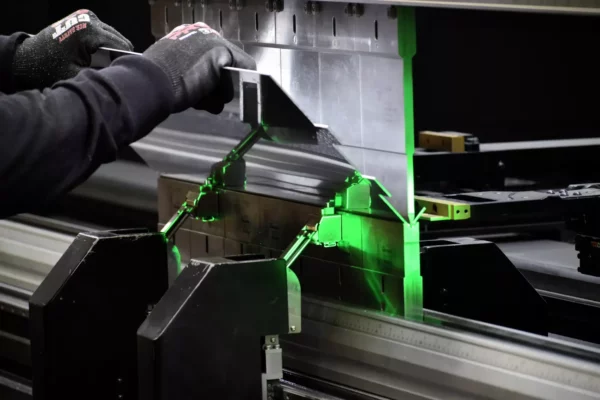

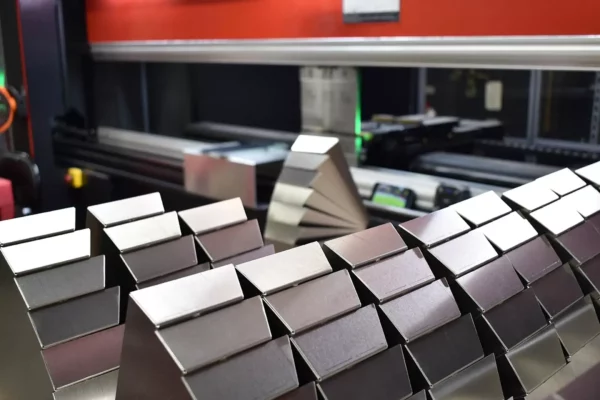

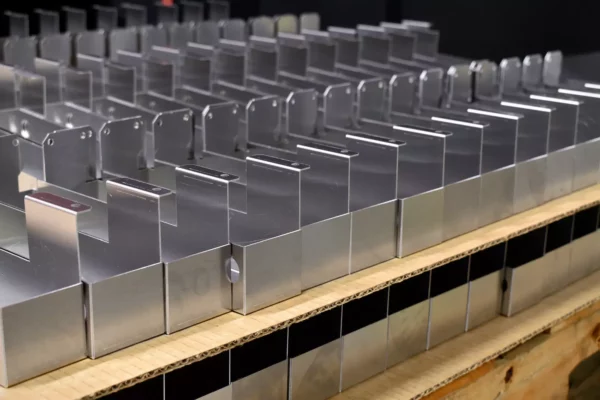

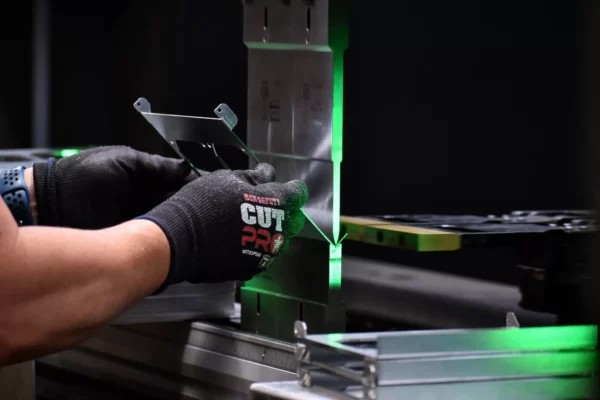

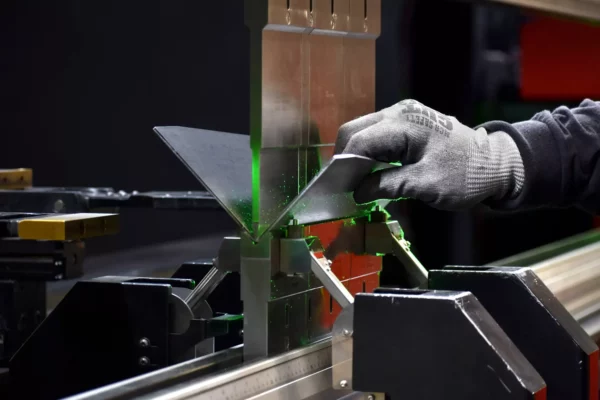

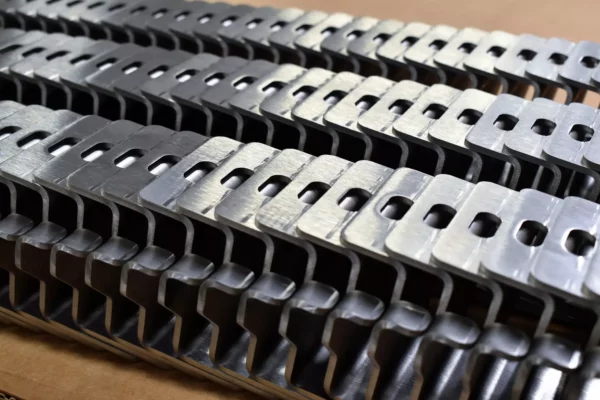

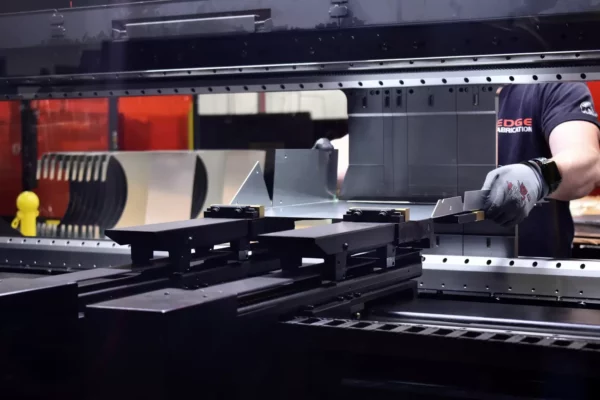

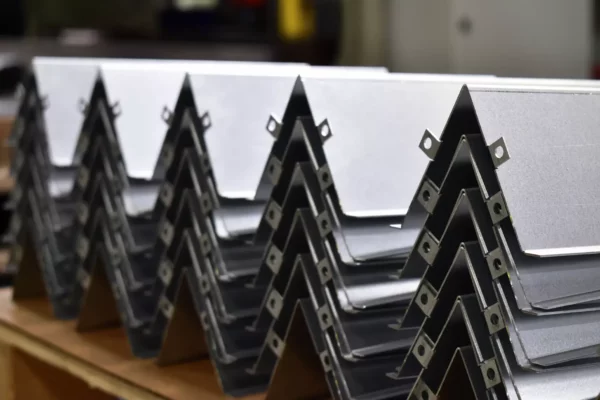

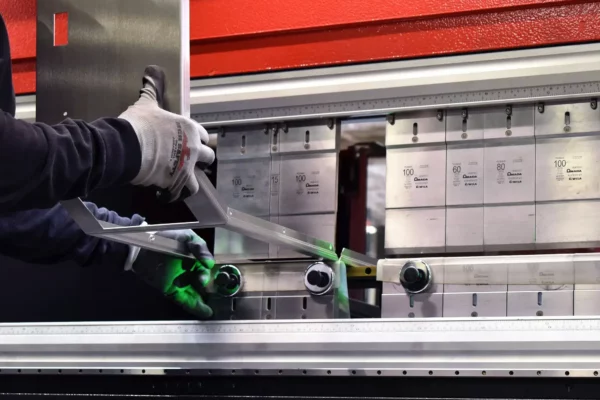

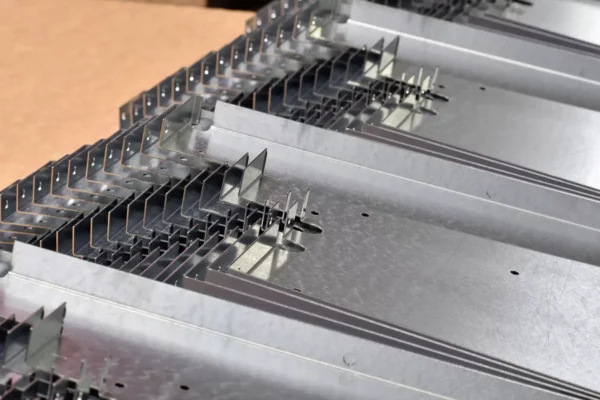

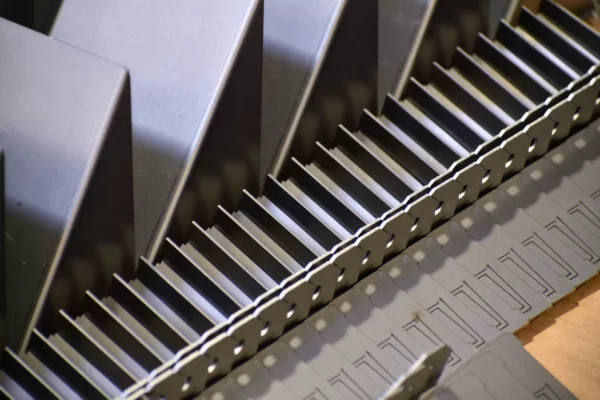

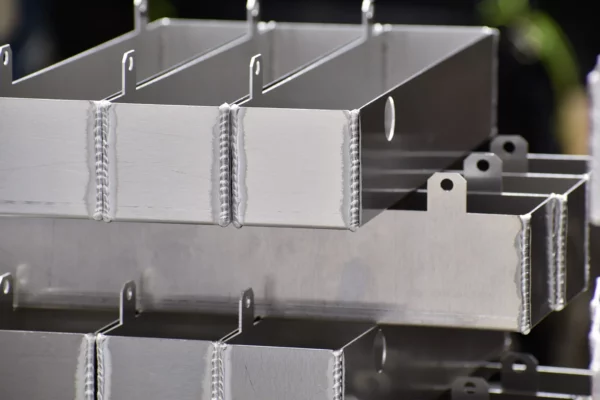

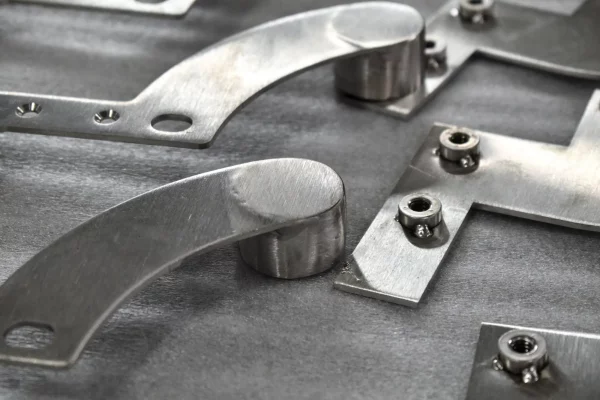

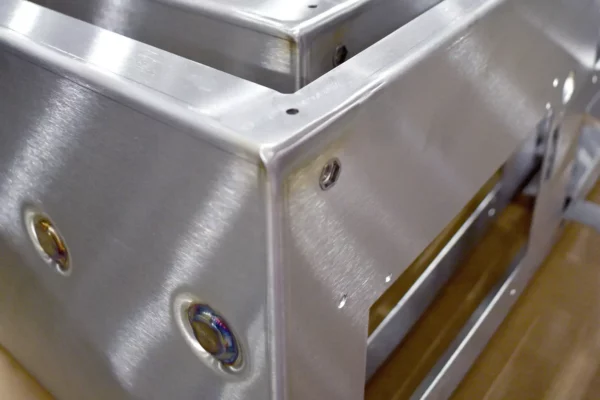

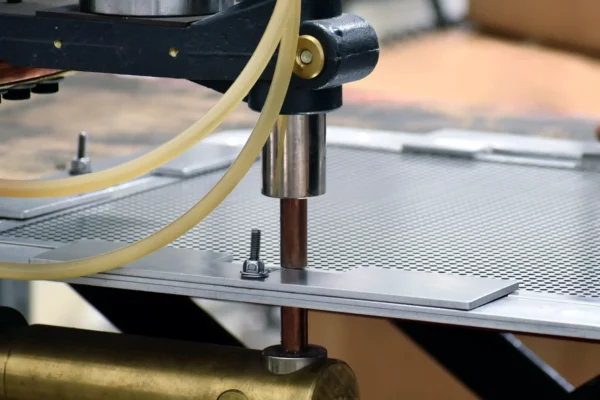

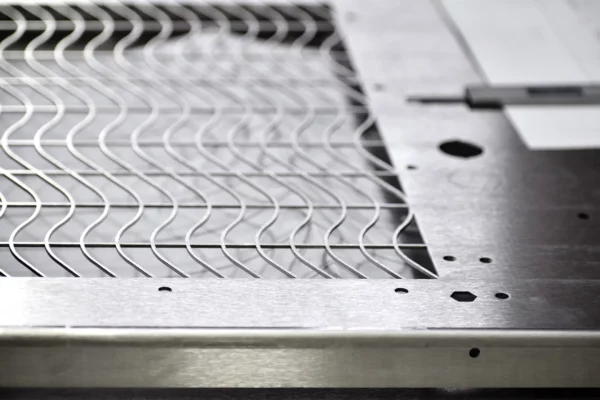

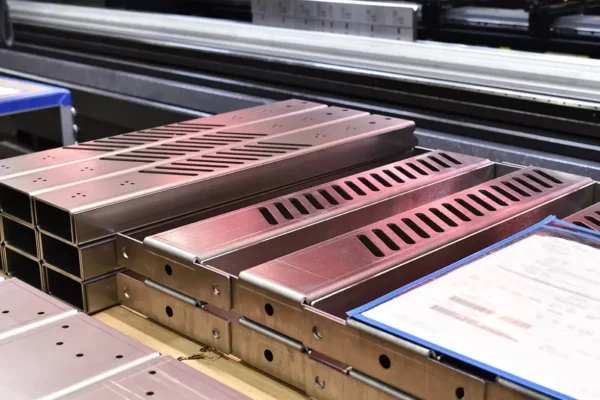

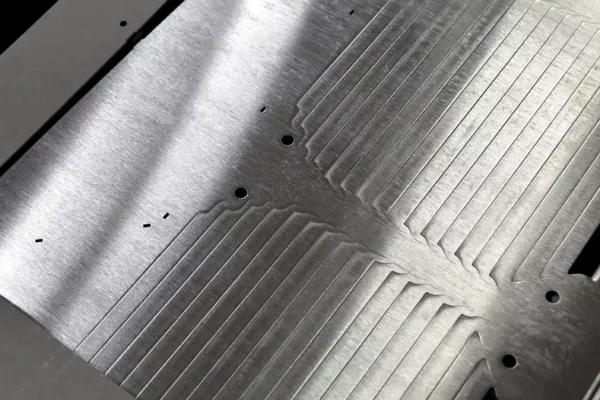

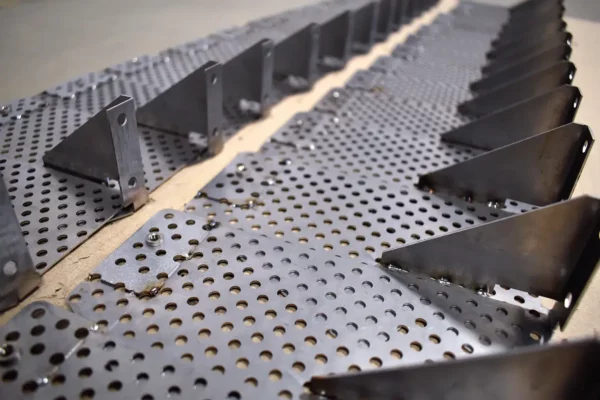

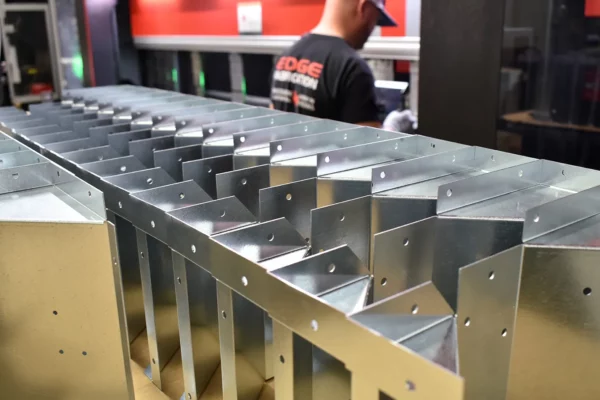

Edge Fabrication offers the latest in sheet metal forming to bring you high quality products as cost-effectively as possible. Our production process starts in the programming stage with bend simulation technology to validate the process and achieve repeatability. Our equipment can produce formed parts with complex geometry over and over again. Our brakes range up to 14ft. bed length and 240 forming tonnage with 4 to 8 axis back gauges, and allow for repeatable process controls.

Accurpress Edge

- 120 ton

- 10 ft. bed

- 4 axis back gauge

Amada HS1303

- 100 ton

- 10 ft. bed

- 6 axis back gauge

Amada HS8025

- 80 ton

- 8 ft. bed

- 6 axis back gauge

Amada HG1003 ATC

- Automatic tool changer

- 110 ton

- 10 ft. bed

- 8 axis back gauge

Amada HG2204 ATC

- Automatic tool changer

- 240 ton

- 14 ft. bed

- 8 axis back gauge