It may be difficult to decide if your project requires laser cutting or a punch press. Both options offer their own unique pros and cons. Our team at Edge Fabrication is here to guide you to the right process for your project to optimize time and cost.

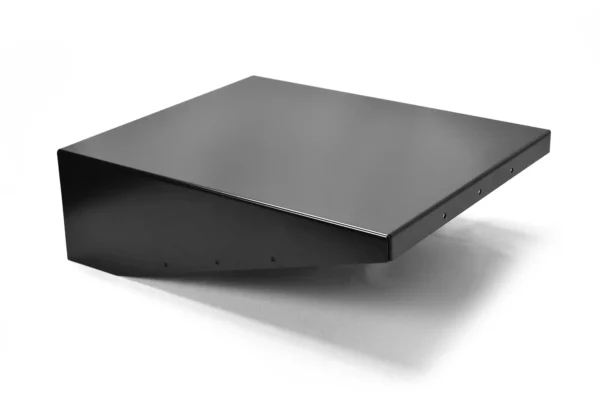

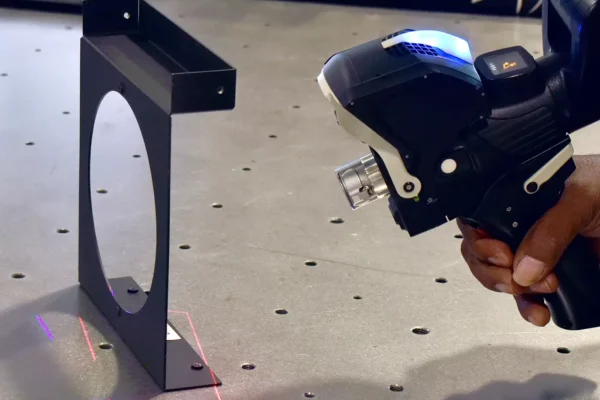

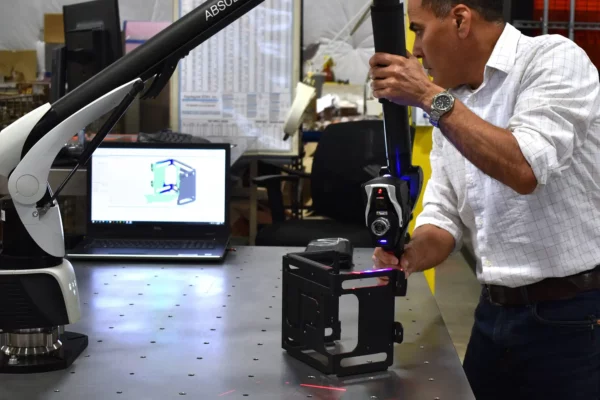

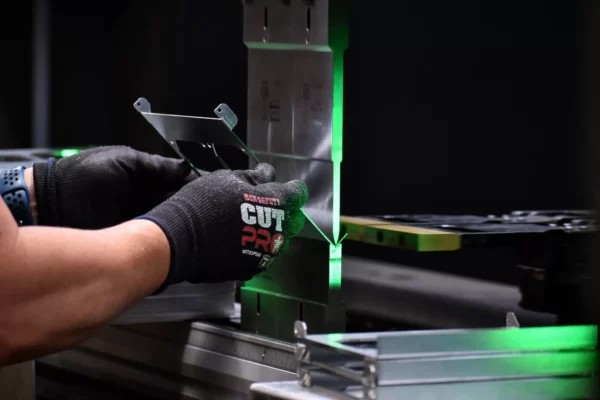

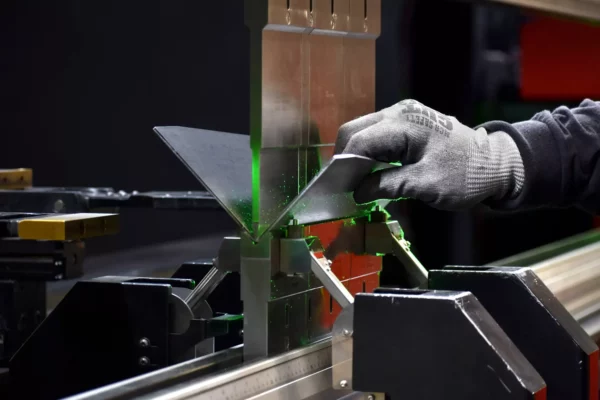

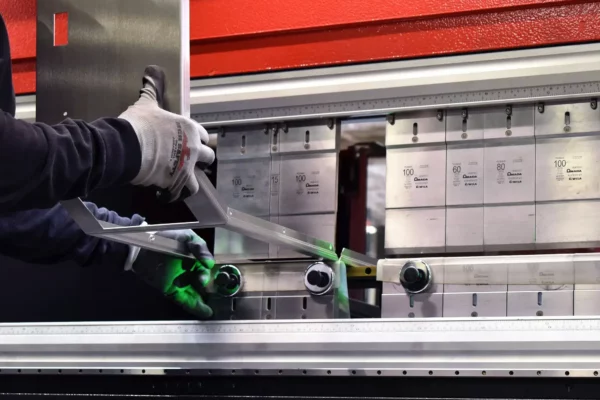

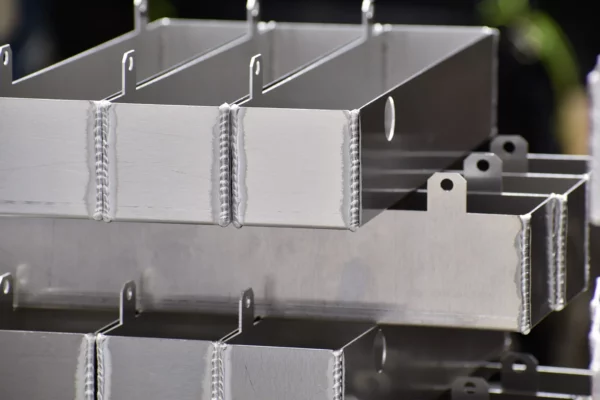

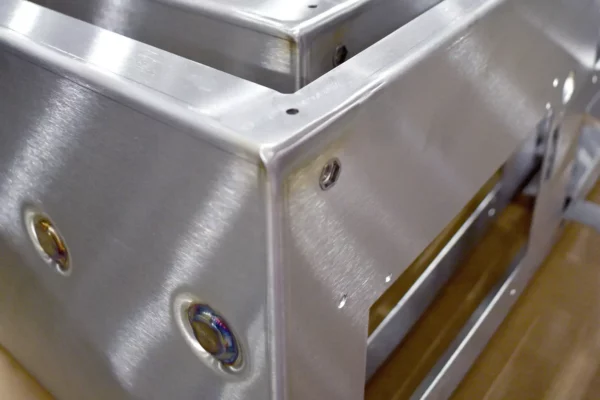

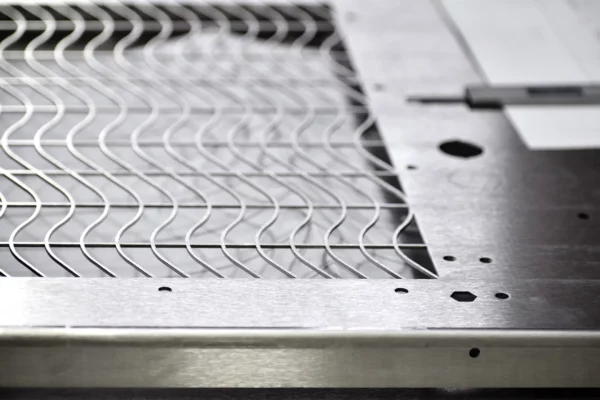

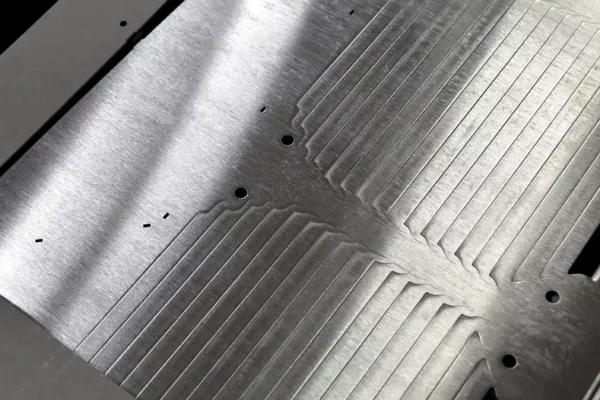

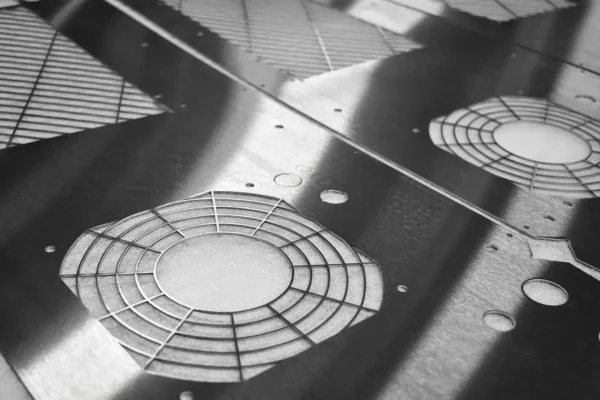

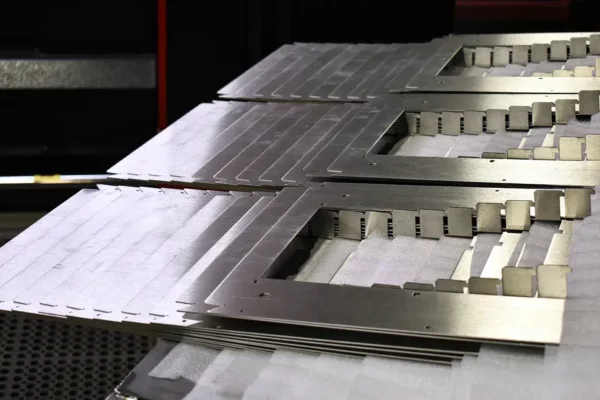

Laser Cutting Services

Laser cutting can dramatically decrease lead times and reduce material scrap while maintaining tight tolerances. It can also reduce costs by eliminating the need for some secondary processes. Unlike stamping, laser cutting does not require tooling and offers practically burr-free holes and edges. Edge Fabrication offers the latest laser cutting technology in order to bring you high quality, cost-competitive, precision parts.

- Max sheet size up to 60 in. x 120 in.

- Processes steel sheets up to 3/8 in.

- Processes stainless steel up to 3/8 in.

- Processes aluminum up to ¼ in.

- Processes galvanized and galvannealed steel up to 11ga

- Lights-Out capabilities using our fully automated sheet loader

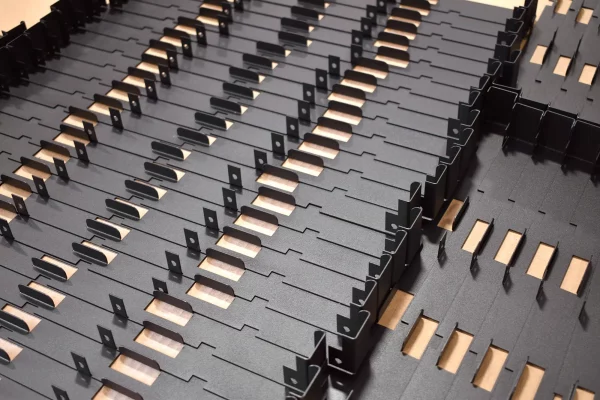

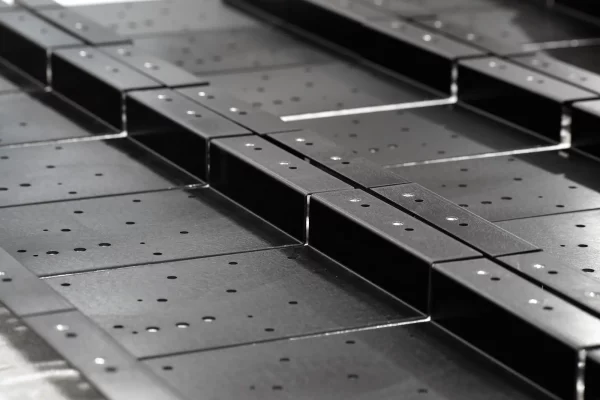

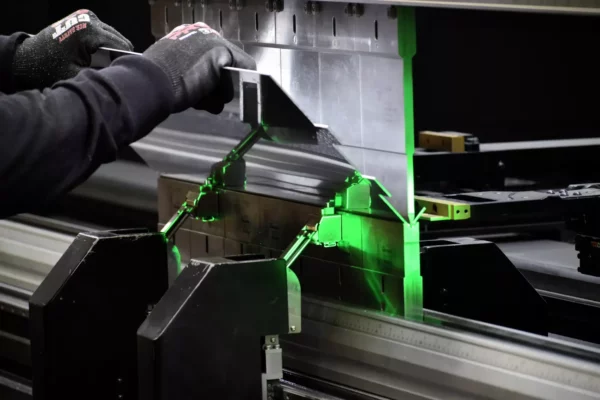

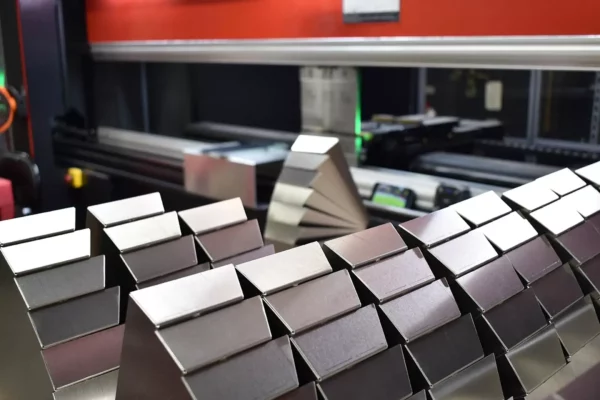

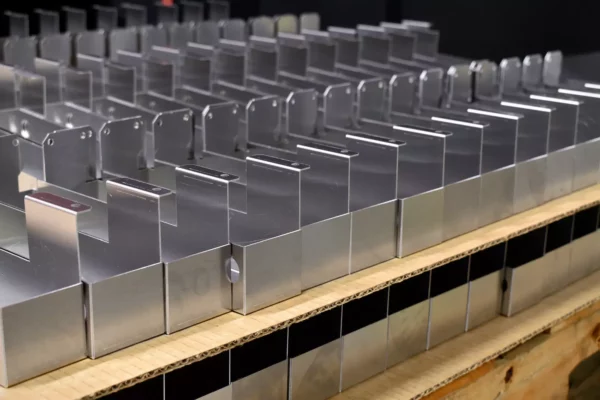

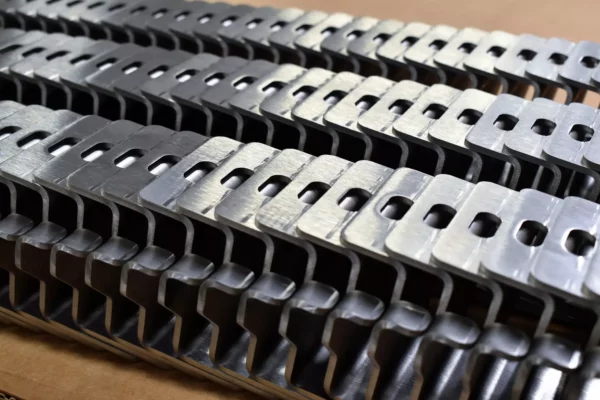

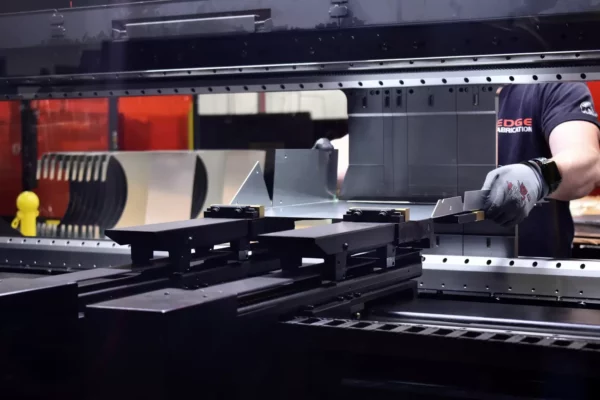

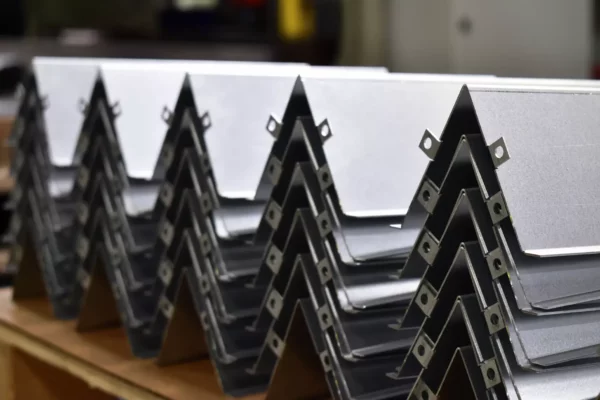

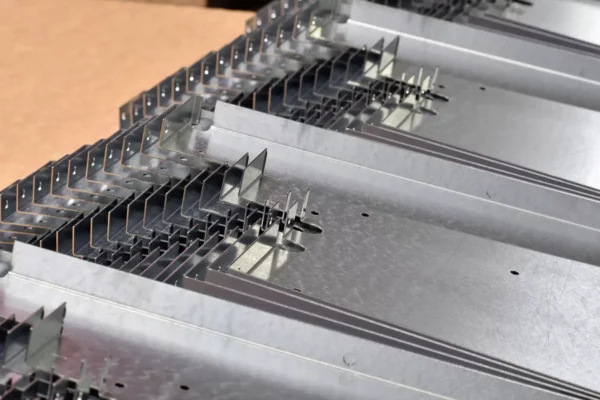

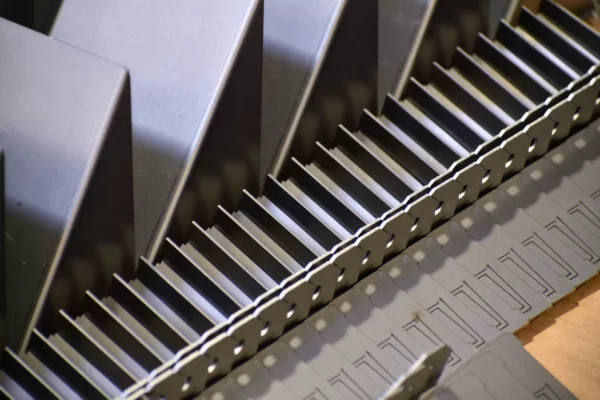

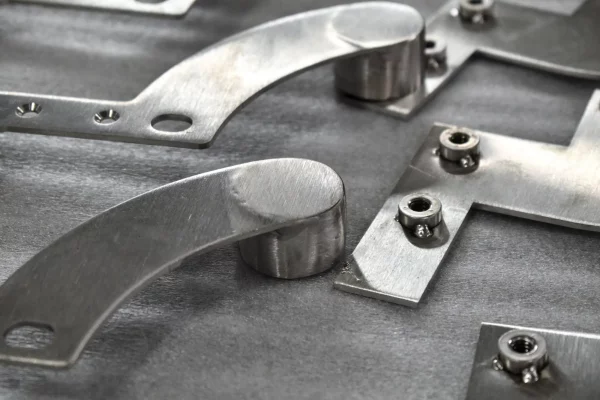

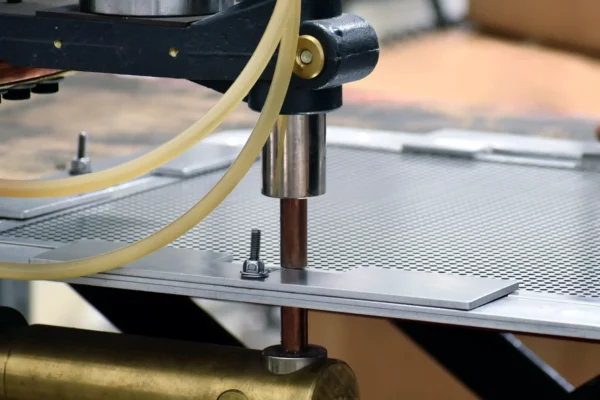

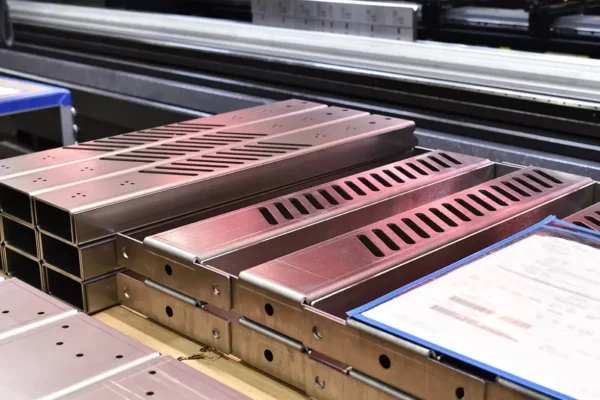

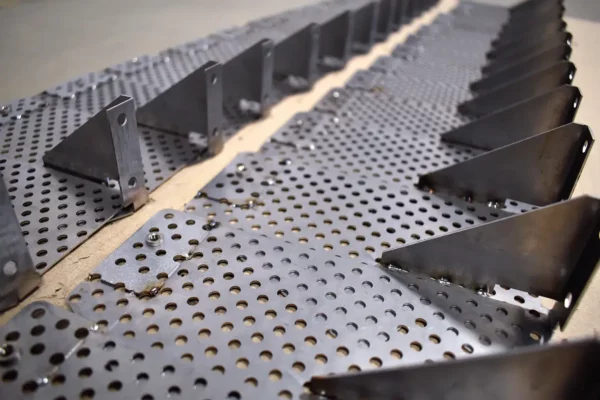

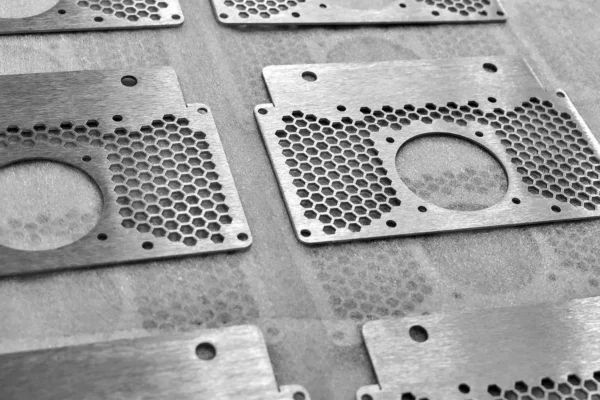

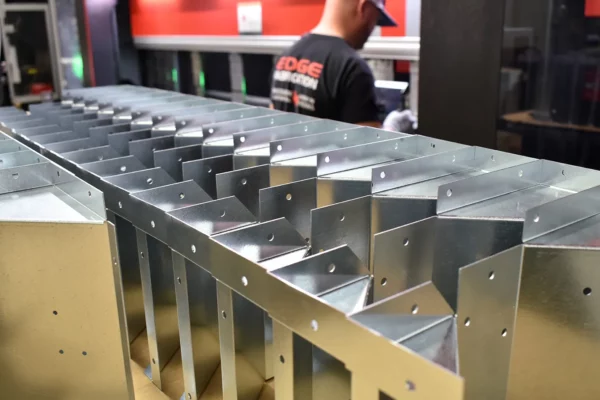

Punch Press Services

One great advantage to using a punch press is the production speed. This can help bring the piece price down on large production runs. Another advantage is in the design flexibility which makes it a great choice for flat blanks that have lots of features. Edge Fabrication offers exceptional punch services using our Amada EML 2515 AJ.

- Max tonnage capacity of 33 tons

- Max sheet size up to 50 in. x 120 in.

- Max sheet thickness of ¼ in.

- Max hole diameter of 4 ½ in.